Technical Paper on Carbon Footprint of Thrust Block

Introduction

Hydraulic thrust forces are created due to change of direction, reduction in diameter, and at the end of pipelines under pressure during operation, which may cause joint separation if anchor blocks or anchoring devices are not provided in the pipeline. One of the most common methods of providing resistance to thrust forces is the use of thrust blocks. But construction of thrust blocks requires immense time and generates a large carbon footprint. Every government, private, and industrial sector is trying their best to cut down on CO2 emissions. Pipeline constructions are lagging in these environmental aspects. This paper showcases various economic and environmental benefits of using double chamber restrained joint pipes and fittings in thrust block locations in a ductile iron pipeline.

Carbon footprint of thrust block

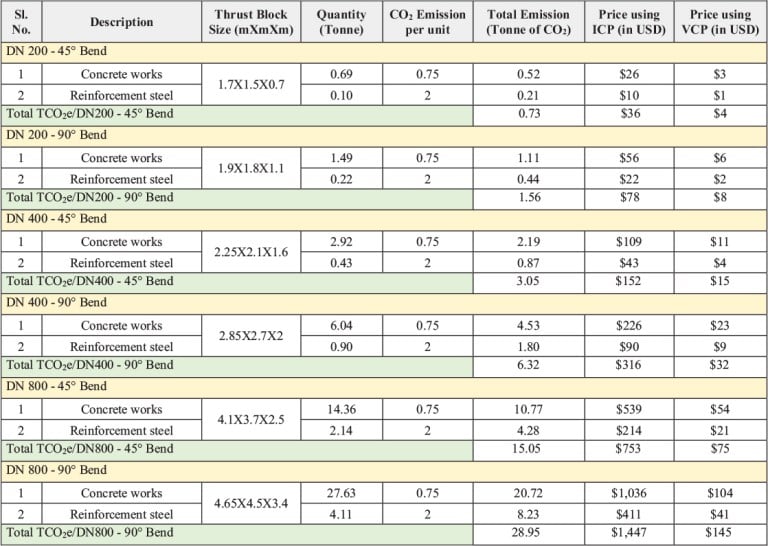

A typical thrust block is made of plain cement concrete (PCC) base with reinforced cement concrete (RCC) above it. Though construction of a thrust block requires several machineries such as excavators, concrete mixing machines, bar binding and cutting instruments. In this paper, only the raw material for construction of thrust blocks is considered.

From literature available online it is found that the carbon footprint of cement and steel are 0.75 ton CO2/tonne of cement and 2 tonne CO2/tonne of steel respectively.

Carbon footprint comparison chart

Carbon pricing

As per the High-Level Commission on Carbon Prices, meeting the world’s climate goals in the most cost-effective way with fostering growth requires individual countries to set a strong carbon price, with the goal of reaching US$40-80 per ton of CO2 by 2020 and $50-100 per ton by 2030.

Sample calculation of total carbon emission from construction of a thrust block in DI pipeline and equivalent value of CO2 emission

Considerations:

- Quantity of cement required for 1 cubic metre of M20 concrete = around eight bags of 50 kg of cement.

- Approximated internal carbon price has been considered as $50/mt of CO2 based on the Carbon Disclosure Project India.

- Approximated voluntary carbon price has been considered as $5/mt of CO2 based on the National Carbon Market.

- Design Pressure =1 MPa and depth of cover = 1 m.

Conclusion

Due to environmental and techno-commercial reasons, ductile iron double chamber restrained joint pipes and fittings are becoming the successor of thrust blocks day to day. Sooner or later, rapid urbanisation in India will force the water and sewerage system to use ductile iron double chamber restrained joint pipes and fittings. Based on international experience, it is evident that carbon pricing cannot be the cornerstone of global climate policy, nor should it be expected to. When India will be ready to consider carbon pricing at the institutional level, climate-resilient technologies such as ductile iron double chamber restrained joint pipes and fittings will replace thrust blocks forever.

Source: indianinfrastructure.com